-

renukaengg.sch@gmail.com -

View Mobile Number - Send SMS

- Send Email

- GST No. 27AFBPC7035F1ZV

Centralized Lubrication System

For more details please click on the links given below

| Business Type | Manufacturer, Supplier |

| Type | Lubrication System |

| Certification | CE Certified |

| Application | Filling Tubes |

| Weight | 100-500kg |

| Voltage | 230V |

| Power | 1-3kw, 12-15kw, 3-6kw, 6-9kw |

| Driven Type | Electric |

| Warranty | 1year |

| Automation Grade | Fully Automatic, Semi Automatic |

| Product Code | Single Line Progressive Type Lubrication |

Single Line Progressive Type Lubrication System that we offer is manufactured using the latest techniques under the guidance of experts. It is subjected to stringent quality tests so as to ensure its defect-free working. We are one of the eminent Manufacturers and Suppliers of Lubrication System. One can obtain Lubrication System from us in small as well as bulk quantities at the most reasonable prices.

Principle of operation : Entire output of the pump is supplied to the bearing points through a distributor/metering device irrespective of varying pipe lines or bearing back pressures.

Construction and Operation

It consists of hydraulics/pneumatic/manual or motorized pump with a single line to the metering device and then to further metering devices or directly to the bearings. There is no return line hence this system can be TOTAL LOSS or can be RECIRCULATING type lubricating system.

This system is very flexible with various types of pumps and progressive distributors up to 576 points. When a motor is started, pump delivers the lubricant under pressure to the distributor from where it is either deliverd to the next distributor in case of large number of points or directly to the bearings. Pecularity of this system is that, unless metered quantity of lubricant is delivered from one particular outlet of distributor, lubricant can’t be delivered from next outlet. This sequential operation makes the system SELF MONITORING type. Thus monitoring of a single outlet is as good as monitoring whole system.

Application

Presses, Packing Machines, SPMs, Textile Machies, Crushers, Construction Machines and Plastic Processing Machines.

| Business Type | Manufacturer, Supplier |

| Type | Centralised Lubrication Systems |

| Certification | CE Certified |

| Application | Filling Tubes |

| Weight | 100-500kg |

| Voltage | 230V |

| Power | 1-3kw, 12-15kw, 3-6kw, 6-9kw |

| Driven Type | Electric, Hydraulic, Mechanical |

| Warranty | 1year |

| Automation Grade | Semi Automatic |

| Product Code | Single Line Injector Type Lubrication Sy |

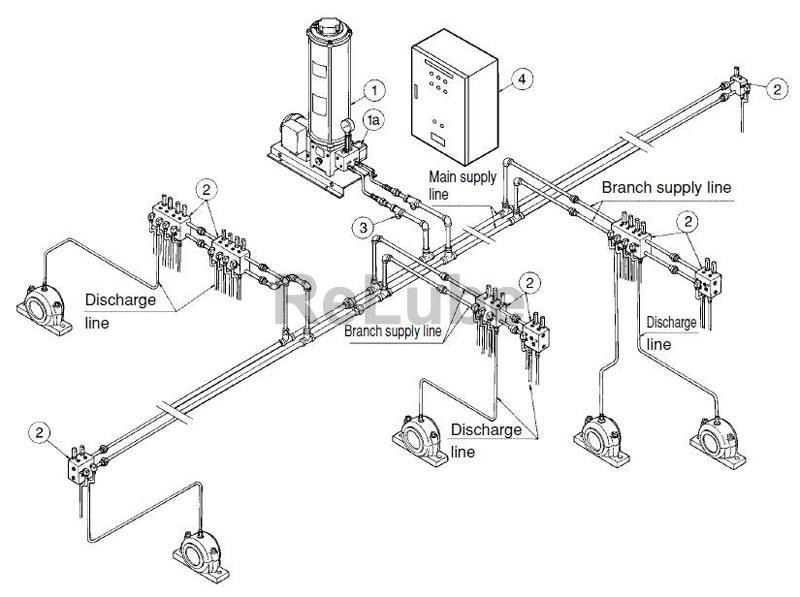

Single Line Injector Type Lubrication System that we offer is manufactured under the guidance of experts by following the set industry standards. We conduct stringent quality tests on Lubrication System so as to ensure that only the defect-free product reaches the customers’ end. We are listed among the top Manufacturers and Suppliers of Lubrication System. Buyers prefer to buy Lubrication System from us as we make it available at a very reasonable price.

Principle of operation : Single main line runs from the pump to the farthest metering valve or injector directly or in branches.

Construction of operation

Lubricant output from pump reaches each metering valve or injector directly from main line. Pressure and flow from pump forces spring loaded pump in the valve to move, dispensing metered quantity of lubricant from measuring chamber to bearings. After all the injectors are operated, further increase in pressure stalls pump and pressure switch it provided sends signal. Then venting cycle starts by reliving the pressurised main branch line and thus makes all the injectors ready for next cycle.

Applications

Glass forming machines, Tyre tube curing presses, Hydraulic Presses, Food processing & Packaging machines, Textile machies and Earthmoving equipments.

| Business Type | Manufacturer, Supplier |

| Type | Dual Line |

| Certification | CE Certified |

| Application | Filling Tubes |

| Weight | 100-500kg, 1000-1500kg |

| Voltage | 230V |

| Power | 1-3kw, 12-15kw, 6-9kw |

| Driven Type | Electric, Hydraulic, Mechanical |

| Warranty | 1year |

| Automation Grade | Semi Automatic |

Dual Line Lubrication System that we offer is well tested and therefore, is the perfect option on which buyers can easily rely. We are reckoned as one of the reputed Manufacturers and Suppliers of Dual Line Lubrication System. Manufactured under the strict vigilance of experts, our Lubrication System is known for its longer functional life. Tested using the latest techniques, our Lubrication System is free from all kinds of defects.

Principle of operation : Two parallel lines run from pump to control valves and from control valves to metering devices and then to bearing points. End of line pressure switch gives signal to change over the line and thus continuous operation is ensured.

Construction & operation

A single outlet pump, 4/2 way direction control valve, metering devices, end of line pressure switches etc. are important parts of the system. In this system, lubricant is supplied from central pump to control valve, which further supplies it to the main lines and ultimately to bearings. When pump os started, one of the main line gets charged, it delivers required quantity of lubricant to bearings and at that time other main line acts as a relief line. When end if line pressure switch sends signal to changeover the line (i.e. half of the total number of lubrication points are covered.) After getting signal from end of line pressure switch, the changeover valve operates and the other main line gets charged and remaining half number of lubrication points gets lubricated. This ensures one complete cycle. Advantages of this system is that the pump used is high volume, high pressure type and number of bearings can be centralised is large (up to 1000 points).

Applications

Sugarcane Crushing Mills, Steel Rolling Mills, Metal Processing Machines, Power Plant Conveyers and Grate Coolers.

| Business Type | Manufacturer, Exporter |

| Type | Lubrication System |

| Certification | CE Certified |

| Application | Filling Tubes |

| Weight | 100-500kg |

| Voltage | 230V, 440V |

| Power | 1-3kw, 12-15kw, 3-6kw |

| Driven Type | Electric |

| Warranty | 1year |

| Automation Grade | Semi Automatic |

Multi-line Lubrication System that we offer consists of multi-outlet pump in which each outlet connected to individual bearing. When multi-outlet pump with progressive distributor, it offers system extension/flexibility to a great extent. Pump outlets are adjustable. A check valve is fitted inside each outlet that ensures positive dispensing. We are counted among the top Manufacturers and Suppliers of Multi-line Lubrication System. It can be obtained from us at the best market price.

Application : Medium and large size Presses, Earthmoving Equipments, Screw Conveyers, Punching Presses, Mixing Mills, Crushers, and Turbines etc.

| Business Type | Manufacturer, Supplier |

| Type | Spray Machine |

| Certification | CE Certified |

| Color | Multi Colour |

| Voltage | 220V, 380V |

| Power | 1-3kw, 3-6kw, 6-9kw, 9-12kw |

| Driven Type | Pneumatic, Electric |

| Warranty | 1year |

| Automatic Type | Manual |

We are named among the renowned Manufacturers and Suppliers of Grease Spray System. In this system, special lubricant is pumped with the help of motorized or pneumatic pump which is then, supplied to progressive metering device through unit of filter and safety valve. Our Grease Spray System is well tested and thus, buying it from us will be the safest option for the buyers.

Mainly two types of spray nozzles are used in this system :

- Monitored : It is monitored by Limit or Proximity switch. It can be operated by progressive dosing of lubricant. The nozzle doesn’t operate unless air and lubricant both are available and at right pressure.

- Unmonitored : In this system lubricant is monitored through limit switch and air is monitored through pressure switch installed after the last nozzle. In this nozzle, spray of specific size is achieved by spraying after mixing of Air & Lubricant.

Application : Open Gear Drives of Cement Mill, Raw Mill, Coal Mill & Kilns & Chain Conveyers.

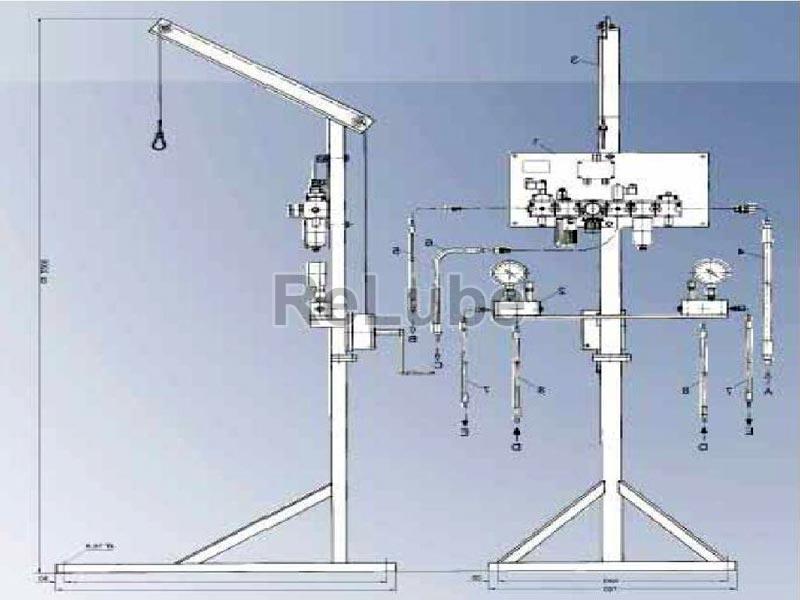

| Business Type | Manufacturer, Supplier |

| Type | Oil Circulating System |

| Certification | CE Certified |

| Weight | 100-1000kg |

| Color | Multi Colour |

| Voltage | 110V, 220V |

| Power | 1-3kw, 3-6kw, 6-9kw |

| Warranty | 1year |

| Driven | Electric |

| Automation Grade | Semi Automatic |

Oil Circulation System that we offer comes with all necessary instruments that are installed at appropriate location for proper measuring of pressure, temperature, level and flow related data. Enough redundancy is built inside the system so that it requires less maintenance. It is perfect for dusty areas as the system is fully enclosed. We can customize Oil Circulation System as per the requirements specified by the buyers.

Flow Range : 0.5 LPM to 500 LPM